Process Manufacturing ERP Software : Cut Costs & Elevate Quality

Implementing Process Manufacturing ERP Software enables businesses to effectively navigate dynamic market landscapes, stimulate sales growth, and streamline cost efficiencies. By centralizing manufacturing operations and harnessing essential features, manufacturers can attain operational excellence.

Process manufacturers face several operational challenges

Explore the features of our ERP software to find effective solutions and ensure your business thrives

Process manufacturers face challenges during their operations. These impact efficiency, profitability, and competitiveness. Implementing ERP software improves data accuracy, streamlines operations, enhances decision-making and ensures compliance, optimizing performance and enabling growth in process manufacturing.

The challenges business might face are:

- Data Management Challenges

- Quality Management Challenges

- Inventory Visibility Issues

- Low Employee Productivity

- Cost Management Problems

- Operational Streamlining

- Improved Decision-Making

- Customer Service Enhancement

- Reduction in Lead Times.

- Scalability Challenges.

Process Manufacturing ERP Software Best Key Features

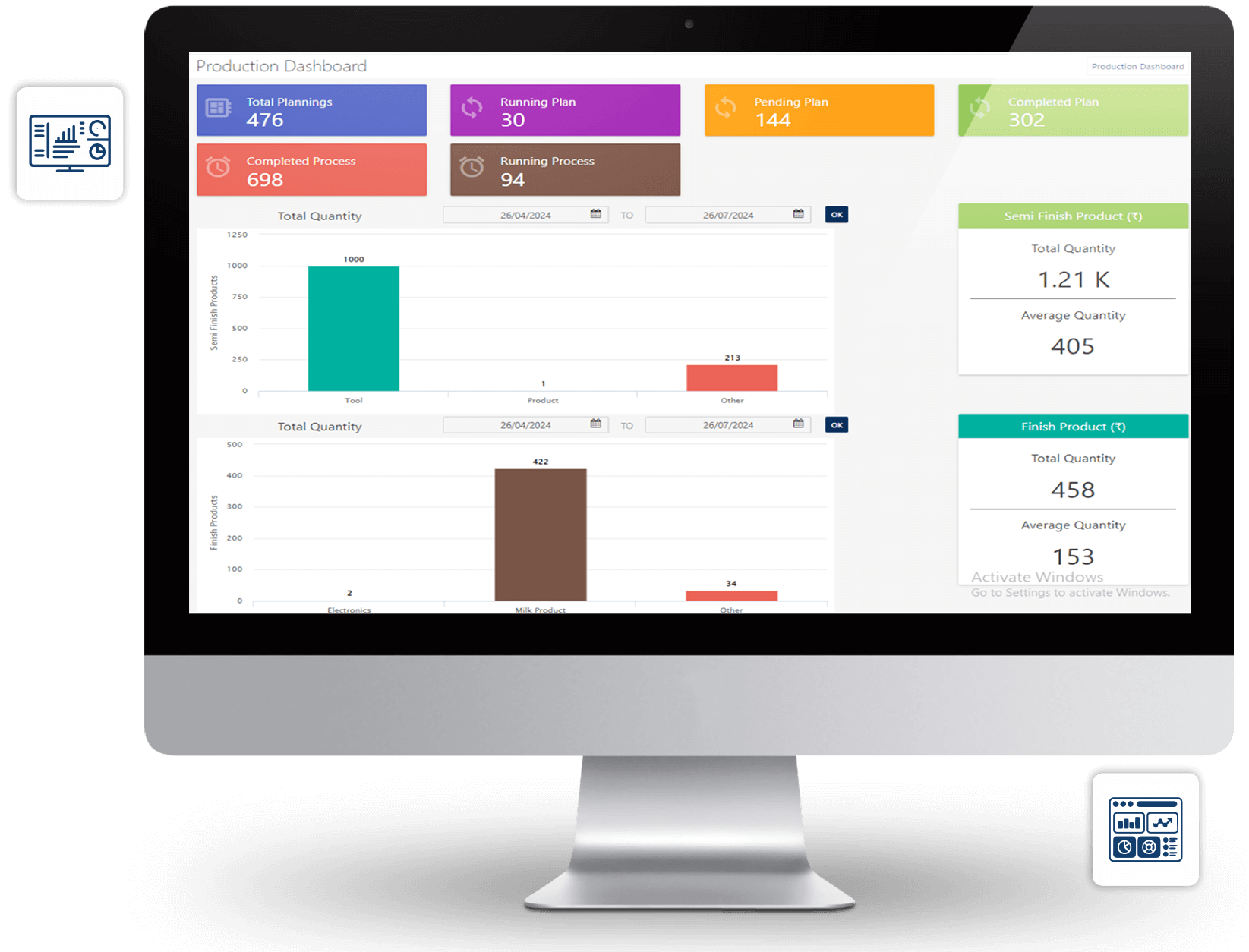

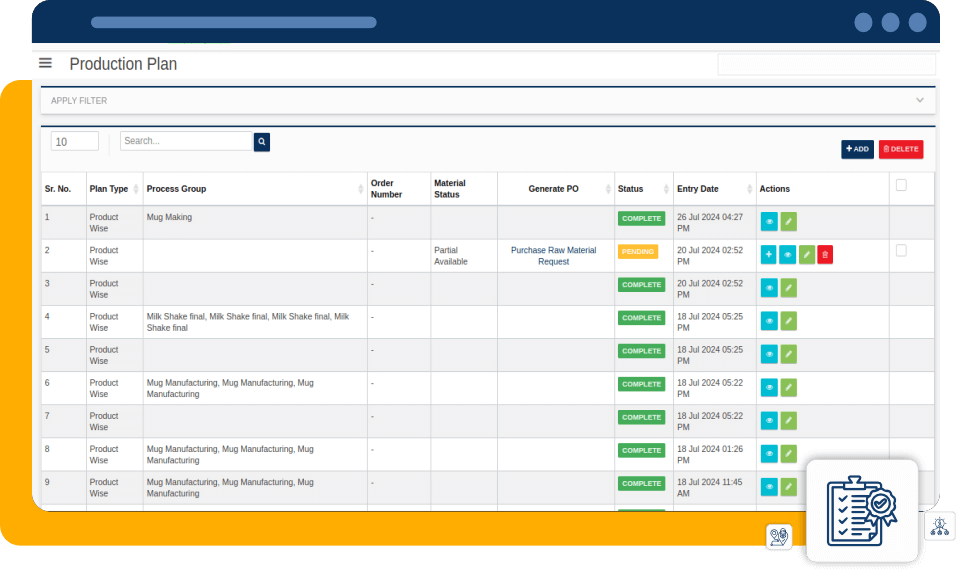

Effective production planning is essential for any business to succeed. It ensures that resources are used wisely, schedules are adhered to, and projects are completed on time.

However, since employees often juggle multiple tasks, they may forget schedules, leading to delays and customer dissatisfaction. Therefore, to simplify production planning, it is crucial to monitor each stage of the production process closely.

Consequently, this ensures optimal efficiency and timely project completion. With clear visibility into every stage, businesses can proactively address issues, thereby maintaining high standards of quality and delivery.

Cost handling in process manufacturing ERP software plays a pivotal role in optimizing business operations. It allows companies to accurately determine production costs by integrating data on raw materials, manufacturing processes, and operational expenses.

Thus, this comprehensive approach helps businesses maintain profitability by precisely calculating margins and setting competitive prices.

Moreover, ERP systems facilitate real-time monitoring of cost fluctuations. This capability ensures timely adjustments in pricing strategies to align with market dynamics, thereby enhancing financial stability.

Inventory management is crucial in process manufacturing ERP systems as it optimizes material stock levels, controls prices, and manages various inventory statuses such as overstock and dead stock.

These systems facilitate efficient tracking and organization of raw materials and finished goods. Consequently, this ensures optimal utilization of storage space and minimizes wastage.

Additionally, by maintaining accurate inventory records and integrating supply chain operations, businesses can enhance operational efficiency. This, in turn, reduces costs and improves decision-making processes, leading to a more streamlined and cost-effective operation.

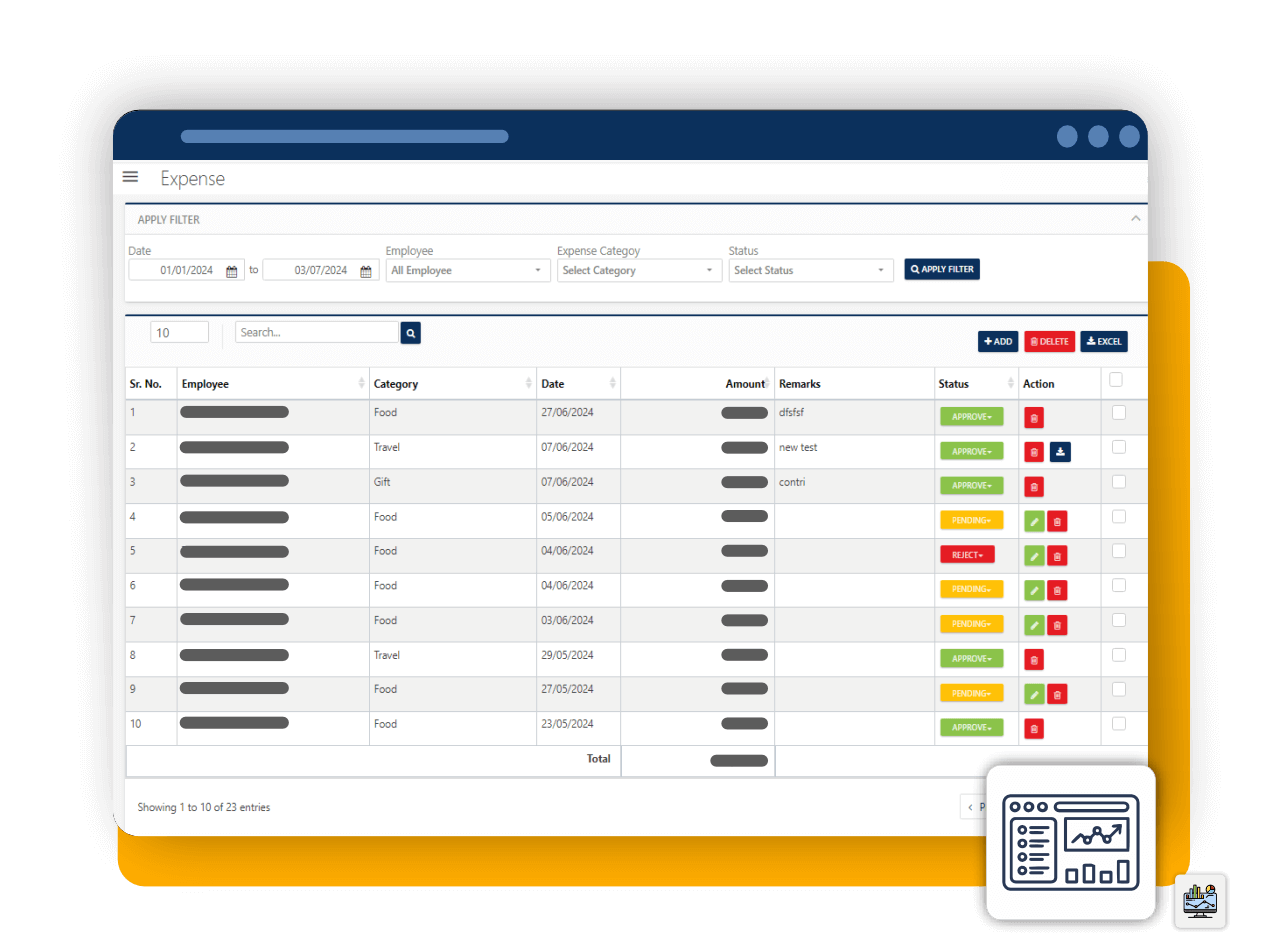

ERP software boosts profitability by optimizing processes, minimizing wastage, and enhancing resource use across production, inventory management, and procurement. It streamlines operations, reduces labour costs, centralizes purchasing for better supplier terms, and scales efficiently as businesses grow. Additionally, real-time insights and analytics further drive cost savings and operational improvements, fostering sustainable business growth.

Ensuring product consistency is crucial for process manufacturing industries as it directly impacts customer trust and satisfaction. Therefore, by defining and standardizing processes to meet specified quality standards and customer requirements efficiently, companies can minimize errors and deviations in production.

This systematic approach enhances customer confidence in product reliability, reduces complaints, and attracts new customers seeking high-quality goods.

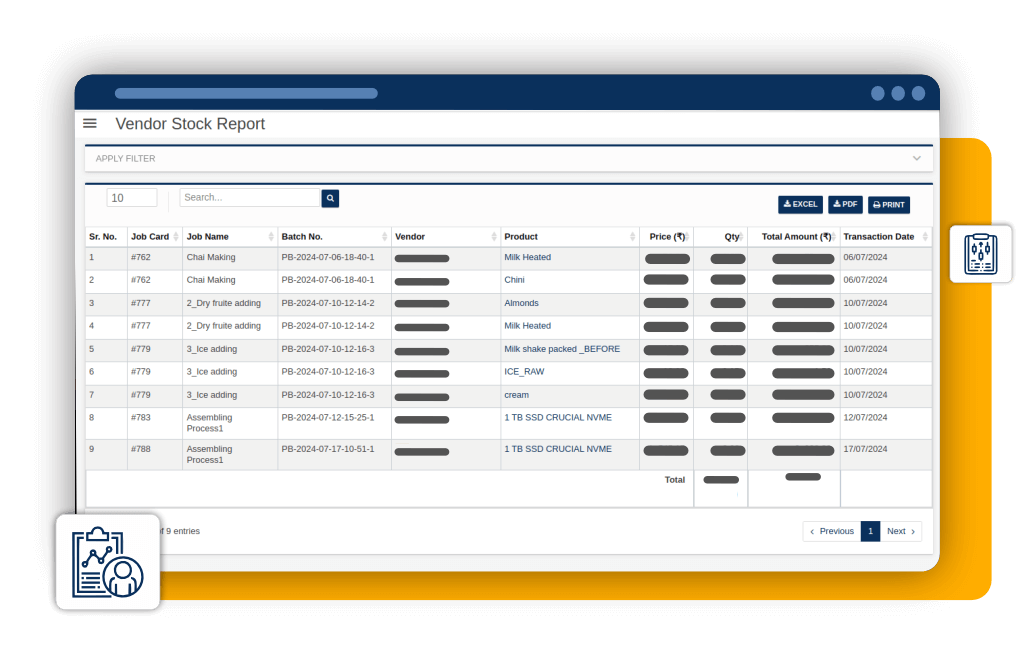

Manufacturers efficiently manage the entire production lifecycle from raw material procurement to final product delivery by leveraging supply chain functionalities within process manufacturing ERP software. This integration ensures streamlined processes, improved inventory management, and seamless outsourced or job work process tracking.

Consequently, these capabilities empower manufacturers to achieve cost savings, enhance productivity, and deliver superior customer satisfaction in a dynamic market environment.

Process manufacturing software integrates forecasting capabilities to optimize inventory levels and anticipate customer demand effectively. With this feature, manufacturers can generate accurate sales forecasts based on historical data and market trends, ensuring efficient supply chain management without excess inventory.

Additionally, the software provides comprehensive reporting tools that analyze forecast accuracy and inventory turnover rates, supporting informed decision-making and enhancing operational efficiency.

Implementing ERP Software significantly boosts employee productivity by streamlining operations, automating routine tasks, and providing real-time insights. Furthermore, this technology eliminates manual processes, reduces errors, and empowers employees by providing tools for efficient planning, scheduling, and collaboration.

Quality Control (QC) is integral to process manufacturing ERP systems, ensuring products meet defined quality standards before customer delivery. It involves systematic processes to monitor production from raw material inspection through final product release. Moreover, by implementing QC within ERP, manufacturers detect and rectify deviations early, minimizing waste and rework costs.

QC in ERP facilitates real-time data analysis and reporting, providing insights into process performance and enabling continuous improvement initiatives.

The Production Tracking System within process manufacturing software enables comprehensive oversight of the production lifecycle from inception to completion. Through real-time monitoring, it ensures both cost efficiency and product quality are maintained without compromise. Manufacturers can accurately track rejection and wastage ratios on a batch-by-batch basis, thereby facilitating proactive adjustments to enhance efficiency and reduce waste.

By centrally sharing data on the product lifecycle status, teams can swiftly devise strategic campaigns tailored to each stage.

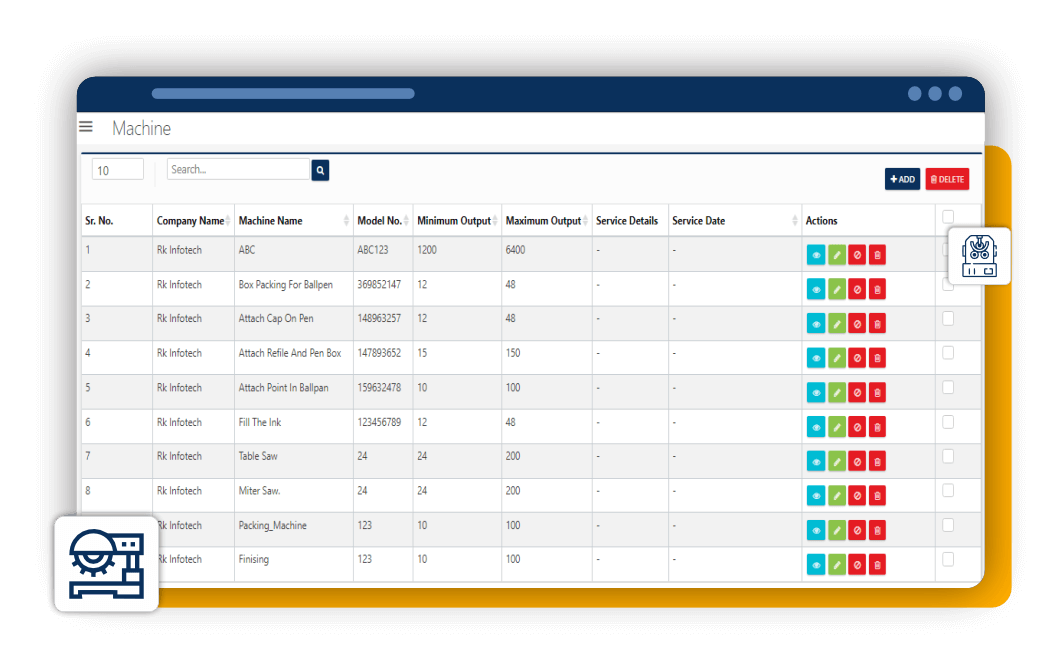

Process manufacturing software facilitates easy monitoring and optimization of performance metrics, enabling streamlined maintenance scheduling and automated data collection across machinery. This enhances operational visibility, reduces unplanned downtime, and significantly boosts productivity.

By leveraging these capabilities, businesses can efficiently manage their manufacturing processes, ensuring seamless operations from start to finish.

Process manufacturing software ensures businesses adhere to industry regulations seamlessly. By tracking batch traceability and maintaining accurate records, guarantees consistent product quality and builds customer trust.

The production bill of materials (BOM) is the structure of your finished goods, outlining the components and quantities required for production, including raw materials, resources (labour, machinery, etc.), and routing stages (such as welding assembly). In process manufacturing software, choosing between LIFO (Last In, First Out) and FIFO (First In, First Out) methods is crucial for efficient inventory management.

While FIFO ensures older materials are used first, ideal for perishable goods industries to minimize waste and maintain quality, LIFO suits industries with volatile material costs, matching recent prices with revenue for better financial management and tax advantages.

In process-to-process manufacturing, effective outsourcing or job work management is essential for optimizing production capabilities. This involves subcontracting specific manufacturing processes to external vendors or partners. Through dedicated process outsourcing management in manufacturing software, businesses can track activities and materials seamlessly.

This enables comprehensive monitoring of outsourced processes, ensuring quality control, timeline adherence, and cost efficiency.

Benefits of Process Manufacturing ERP Software

- Efficient Inventory Control and Management

- Enhanced Employee Productivity and Task Management

- Cost Reduction Strategies and Financial Management

- Streamlined Supply Chain Operations

- Automated Report Generation and Analysis

- Effective Planning and Scheduling

- Ensuring Product Quality and Consistency

- Customer Relationship Management and Support

- Effective Process Outsourcing ( Job work ) Management

- Precise Batch wise costing and Bill of Materials

Process-to-process manufacturing software revolutionizes production efficiency across various industries such as :

- Kitchenware

- Pumps

- Ceramics

- Food Manufacturing

- Furniture Hardware

- Medicines

- Cosmetics

- Plastics

- Metal

- Lubricate Oil

What Our Client Say About our ERP Solution?

Implementing process-to-process manufacturing software from has been transformative for our operations. It has streamlined our production sequences, enhanced efficiency in material transformations, and improved overall product quality.

Choosing Delight ERP for our process-to-process manufacturing needs was a game-changer. The software has optimized our production workflows, allowing us to manage complex manufacturing stages with ease. It has significantly improved our output consistency and enabled us to meet stringent industry standards.

- Comprehensive process-to-process Manufacturing.

- Batch-wise cost management and pricing strategies

- Efficient inventory control and supply chain management

- Effective Process Outsourcing Management

- Integrated quality control and compliance features

- Streamlined machinery management for reduced downtime

- Seamless tracking of Material and stock

- LIFO / FIFO method base product stock management

- Real-time insights and analytics for informed decision-making

- User friendly interface

- Dedicated Support and Training

Process manufacturing Solution is the software designed to track and manage sequence-wise activities during production in industries where products are manufactured in bulk quantities through processes such as mixing, refining, or blending, rather than discrete assembly.

The software typically includes features like production planning, batch processing, recipe management, quality control, inventory management (including FIFO/LIFO), regulatory compliance tools, and supply chain integration. These features are essential for managing complex manufacturing processes efficiently.

It ensures adherence to regulatory requirements by maintaining accurate records, batch traceability, and documentation throughout the production process.

Yes, it optimizes inventory management by tracking raw materials, work-in-progress, and finished goods. The software provides real-time visibility into inventory levels, enables efficient stock replenishment, and minimizes waste through accurate demand forecasting and material requirements planning (MRP).

Sure, you can get the free quotation and free software demo. Please refer the below links

For Software demo: Click Here

For quotation: Click Here