Production Management Software: Drive Success with Great Quality, and Minimize Cost

Production Management Software streamlines manufacturing from planning to execution by integrating production, scheduling, inventory, quality control, and reporting. For profitability and better operations, it increases output, lowers costs, guarantees quality, and makes data-driven decision-making easier.

Production Managers confront several operational challenges

Production manufacturers face operational challenges affecting efficiency, profitability, and competitiveness. Implementing ERP software can help you counter all the challenges that managers face in day-to-day operations.

The challenges business might face are:

- Inadequate Production Monitoring and Coordination

- Delayed or Inaccurate Information

- Complex Management of Standard and Contract Manufacturing

- Inefficient Sales Process

- Suboptimal Customer Service

- High Internal Costs

- Inventory Management Issues

- Quality Control Challenges

- Compliance and Regulatory Requirements

- Lack of Data Integration

Explore the features of our ERP software to find effective solutions and ensure your business thrives.

Production Management Software Best Key Features

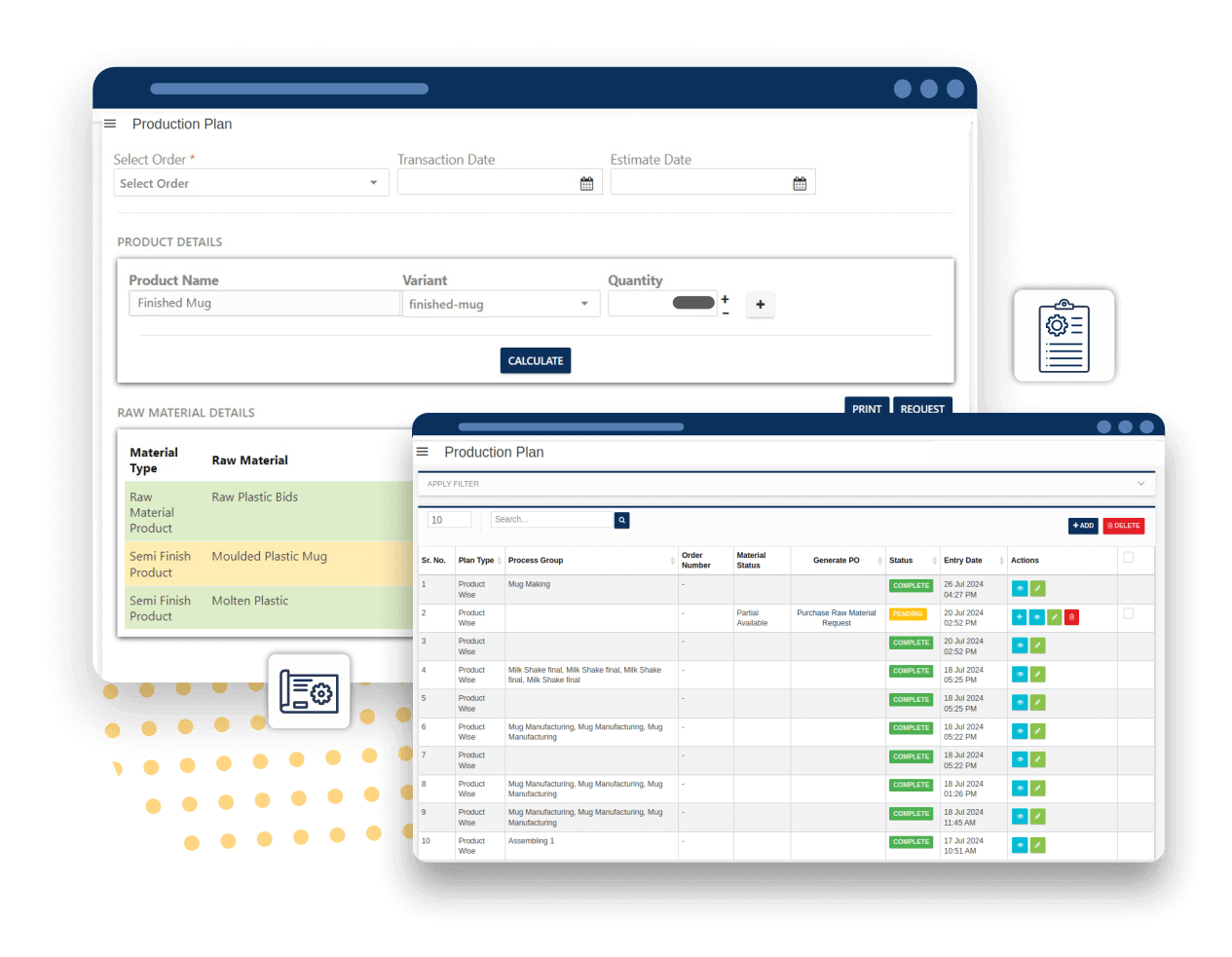

Effective production planning and execution are critical for optimizing manufacturing operations. This involves the meticulous management of routing, scheduling, loading, dispatching, follow-up, inspection, and feedback. Consequently, using advanced software these tools streamline processes, enhance resource efficiency, and maintain quality standards, ensuring seamless production flow and minimal waste.

By leveraging production management systems, companies can achieve operational excellence, meet customer expectations consistently, and adapt swiftly to changing demands

Production management software, integral throughout the entire production lifecycle, begins with planning and scheduling to optimize workflows and resource allocation within the product management system. It tracks manufacturing processes in real time, ensuring efficiency and providing insights into production status. During the growth phase, the software scales operations, manages inventory effectively and maintains consistent quality.

As products reach maturity, it supports competitiveness through data-driven analytics for efficiency gains and cost reductions while upholding product standards. In the decline phase, it aids in evaluating market trends, optimizing resources, and making informed decisions to minimize waste.

Manufacturers use the BOM method to precisely specify product specs, order details, and raw materials. On the other hand, problems like excess raw material inventory can affect monthly earnings. Increased sales and efficient production cost management are prerequisites for businesses looking to maximise revenue, which makes BOM essential.

Production management software is used by businesses to analyse raw material data and make well-informed purchase decisions that optimise revenue and costs. Timely production and delivery are essential for customer satisfaction and can be ensured through effective inventory management.

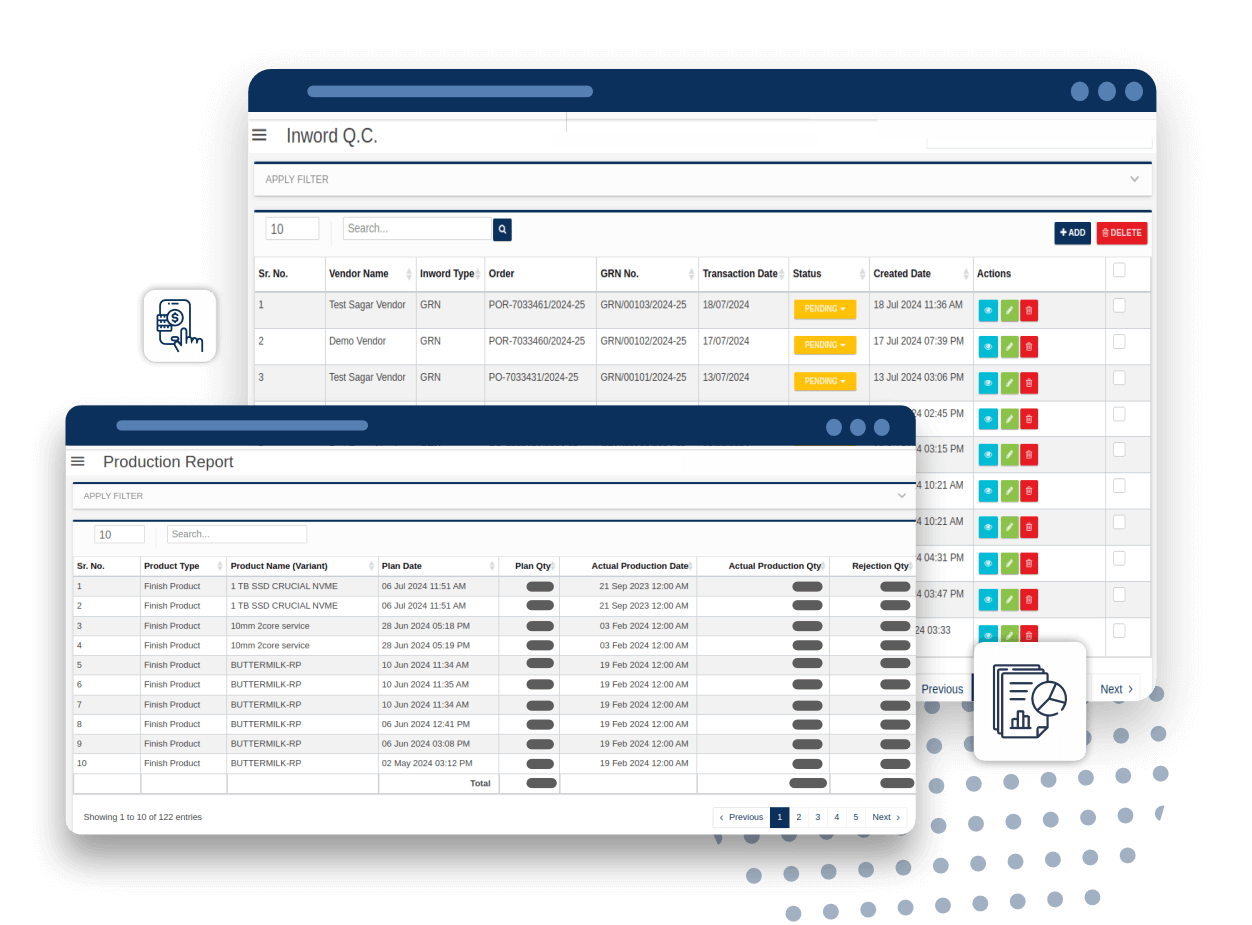

One advantage of production management software in ensuring quality is its capability to streamline and automate quality assurance processes. It facilitates real-time monitoring of production metrics and quality parameters, allowing quick identification and resolution of any deviations or issues. By maintaining comprehensive records and analytics, the software enables continuous improvement initiatives, helping organizations refine their production processes for enhanced efficiency and superior product quality.

Utilising this system, compute yields and final product costs effectively. This application makes it easier to quickly analyse the profitability of a product by automating the capturing of production costs. It makes it possible to create reports that evaluate pricing competitiveness and offer market positioning data.

This ensures thorough financial transparency for manufacturing processes by providing choices to include or exclude rejected units in cost estimates and by computing batch-to-batch expenses.

Pricing methods are optimised in Production Management ERP systems to set competitive prices for different resources and products. This boosts profitability by making dynamic modifications based on market trends. The ERP tracks revenue, expenses, and budget allocation, enabling accurate financial analysis as well.

Furthermore, through batch-to-batch inspections, and batch-wise costing, the system guarantees pricing consistency, enhancing operational efficiency and financial transparency throughout many production cycles.

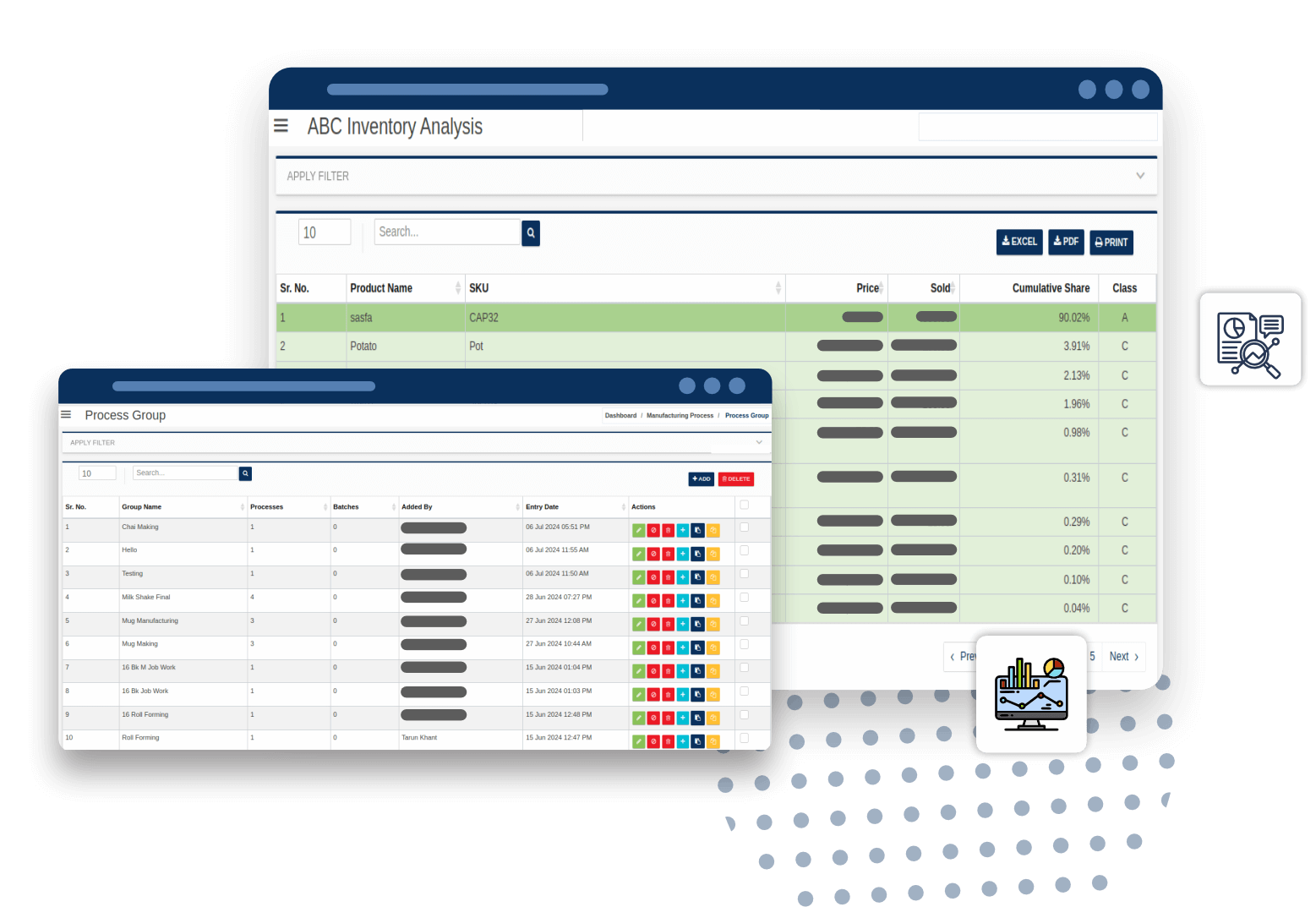

ERP systems for process manufacturing must provide inventory management to optimise material stock levels and control inventory statuses like dead stock and overstock. Production management software makes it possible to closely monitor and minimise waste generation, which is essential for cutting losses and streamlining workflows.

Efficient processes and thorough analysis provide the best possible use of raw materials and increased output for the business, increasing productivity and avoiding overproduction.

Production management system significantly reduces costs by optimizing resource allocation and streamlining operations. It enhances efficiency through automated scheduling and real-time monitoring, which minimize downtime and improve productivity. Additionally, the software facilitates accurate forecasting and inventory management, ensuring that materials are procured at optimal prices and quantities.

Vendor Stock Reports, Aging Reports, and Scrap Reports are effortlessly generated using our Machine Manufacturing Management Software. These reports enable businesses to decrease costs and identify opportunities to increase profits. By collaborating with employees and reviewing departmental information, companies can swiftly adjust plans and workflows.

Effective production process measurements ensure actions, products, or services remain profitable, ultimately boosting overall revenue.

Production management software makes identifying and allocating materials cost-effectively easier, optimising resource use and cost control. It also offers criteria for batch-to-batch comparisons and information regarding vendor rejection and acceptance rates.

Businesses can improve profitability and streamline operations by automating these processes and allocating resources precisely while implementing thorough quality control procedures.

Quality Control (QC) is essential in the process of manufacturing ERP systems to maintain high product standards before customer delivery. From raw material inspection to final product release, QC ensures adherence to quality benchmarks. Production Management Software enhances QC with real-time data analysis and reporting, providing insights into process performance. By proactively monitoring and correcting deviations, QC reduces waste and rework costs, improving production efficiency and product quality.

The software coordinates departments for timely raw material release, smooth production, and punctual delivery, optimizing operational efficiency and customer satisfaction.

Benefits of Production Management Software

- Streamlined production planning and scheduling

- Real-time production tracking and monitoring

- Efficient inventory management

- Enhanced resource allocation

- Automated production processes

- Improved quality control

- Cost reduction through waste minimization

- Integrated supply chain management

- Data-driven decision-making

- Enhanced operational efficiency

What Our Client Say About our Manufacture ERP Solution?

Implementing process-to-process manufacturing software from has been transformative for our operations. It has streamlined our production sequences, enhanced efficiency in material transformations, and improved overall product quality.

Choosing Delight ERP for our process-to-process manufacturing needs was a game-changer. The software has optimized our production workflows, allowing us to manage complex manufacturing stages with ease. It has significantly improved our output consistency and enabled us to meet stringent industry standards.

- Complete manufacturing solutions from start to finish.

- Effective pricing and cost control for individual batches.

- A simplified supply chain and ideal inventory control.

- Skillful handling of outsourcing procedures.

- Features for compliance and quality control integrated.

- Smooth management of the machinery to cut down on downtime.

- Stock and material tracking in real-time.

- Stock management techniques based on LIFO/FIFO.

- User-friendly interface

- Dedicated Support and Training

The software enhances efficiency by effective production planning, scheduling, and inventory management. It improves quality control through real-time monitoring and reduces operational costs by optimizing resource utilization.

The software tracks inventory levels in real-time, ensuring accurate stock management and minimizing wastage. It enables businesses to forecast demand, optimize reorder points, and streamline supplier relationships for efficient inventory management.

Yes, modern software systems are designed to integrate seamlessly with other business systems such as CRM (Customer Relationship Management), This integration enhances data accuracy, facilitates cross-functional collaboration, and improves overall business processes.

Key features to consider include production planning and scheduling, inventory management, quality control, reporting and analytics, resource allocation, real-time monitoring, and scalability. Look for software that meets your industry-specific needs and offers robust support and training options to maximize its effectiveness within your organization.

Sure, you can get the free quotation and free software demo. Please refer the below links

For Software demo: Click Here

For quotation: Click Here